Rugged, long lasting and easy to maintain

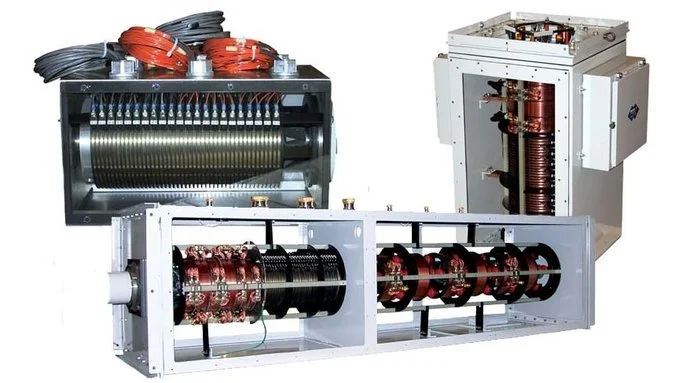

SLIP RING ASSEMBLIES

Conductix-Wampfler Industrial slip rings provide the solution to the problem of passing electric power and signals from stationary to rotating machine members.

We Build Custom Designs

We build customized designs for the application, and quicker than anyone else in the market and at competitive prices. We feature:

Knowledgable Application Specialists dedicated to help you with your unique slip ring problems

Design engineers with hands-on experience using the latest in solid modeling software and R&D equipment to explore and test new designs and concepts

Assembly work cells dedicated to each major product lines to speed assembly

A full-function machine shop with the latest in CNC equipment and in-house metals cutting, welding, and finishing systems

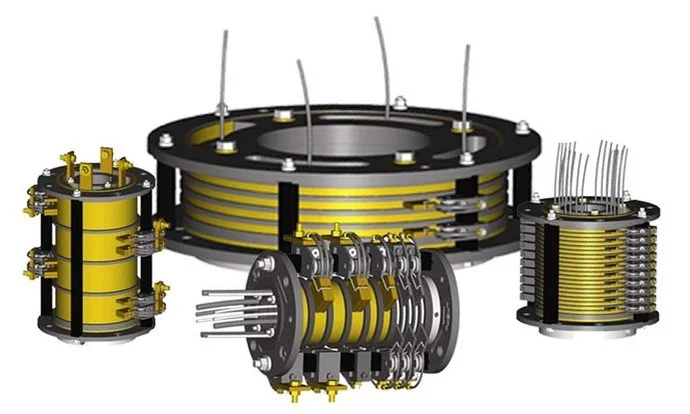

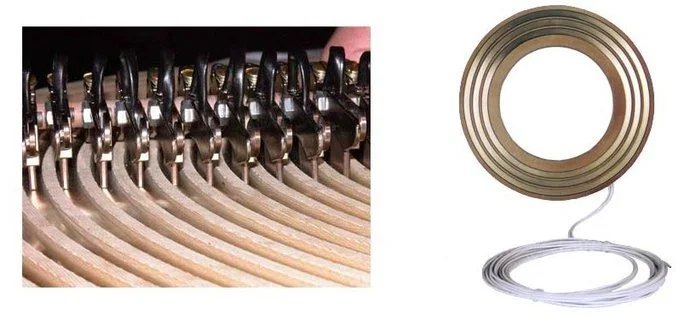

Our flagship line - R-Series - set the standard for quality in industrial slip ring design. They are rugged, built for long life, and easy to maintain. With an assortment of ring sizes, insulators, and bore sizes, we can assemble a ring that is ideally suited for the application. Changing brushes is easy. Each brush can be rotated out of the holder without special tools. Individual brush holders can be removed independently.

Each assembly includes a fully articulating brush system that will track the ring without fail. Rings are sized based on bore size, combined with appropriate ring sizes to meet the electrical need. We sell rings "non-enclosed" and "enclosed". We also sell them for hazardous locations and can integrate fiber optic swivels and/or pneumatic or fluidic rotary joints to the basic electrical slip ring.

Non-Enclosed Slip Ring

Assemblies

Versatile, modular R-Series Slip Rings provide you with a "customized" unit at the price and lead time of an off-the-shelf slip ring! Standard sizes with infinite possibilities for all collector ring applications! Need something special? Give us a call with your application!

Standard Bore sizes: 1.5" thru 10"; custom bore sizes available

Standard Ampacity selections: signal level, 15 amps, 35 amps, 75 amps, 110 amps, 150 amps, 225 amps, 300 amps, 400 amps, and 600 amps.

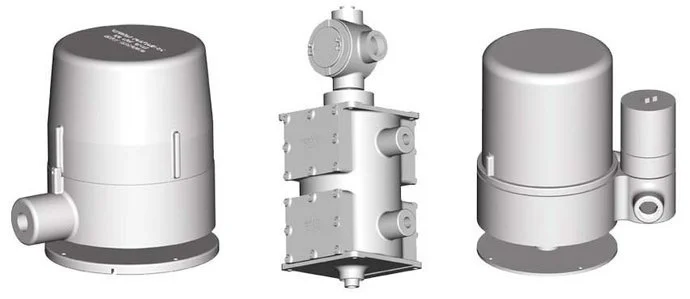

Enclosed Slip Ring Assemblies

Conductix-Wampfler offers several standard slip ring enclosures, all of which can be modified to suit your collector ring application!

Wraparound Cover: NEMA 1 protection - brushed stainless steel

Revolving Unit: NEMA 4 water and dust protection - painted steel

Swivel Unit: NEMA 4 protection in an "inverted Revolving Unit"

Stainless Steel Enclosures: NEMA 4X corrosion protection

Hazardous Duty Slip Ring Assemblies

Conductix-Wampfler offers several standard hazardous duty enclosures built to conform to UL and NEC standards: Class I Divison I Groups C & D (Zones 1 and 2), and Class II Groups E, F, & G standards, and Class III. Versions are offered to fit most common slip rings.

Revolving Unit: Available in common configurations as well as customized versions

Swivel Unit: Single and double housing versions

We can build custom explosion-proof slip ring unit and enclosures with pass-throughs for air or fluids!

High Voltage Slip Ring Assemblies

Need higher than 600 volt capacity? Conductix-Wampfler can modify our standard 600 volt rings to handle up to 2000 volts. If you need even more voltage, we build two basic types of High-Voltage Slip Rings - solid core and air-gap. HV Rings are used in large cranes, mining machines, logging cranes, large cable reels, and other machines requiring more than 2,000 volts.

We build:

Solid-core High Voltage units for 5 to 8 KV duty

Air-gapped High Voltage units for 15 KV and 25 KV duty

These can be combined with multiple circuit types and mounted in enclosures.

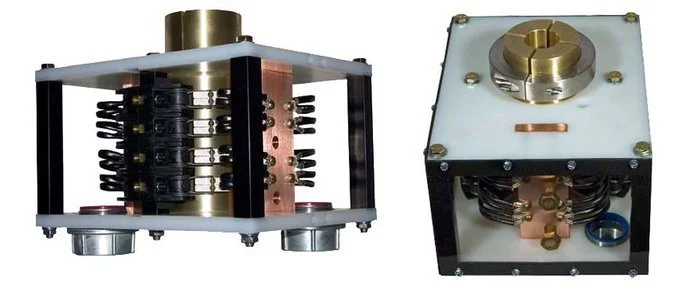

High Amperage Slip Ring Assemblies

Do you need more than 600 amp ring capacity? If so, Conductix-Wampfler can handle it! We have built rings with capacities of 1000 amps, 2000 amps, 3000 amps and more! Our modular brush holders can be bussed together to achieve high current carrying capacity. We have made special configurations for plating line, welding, and grounding applications.

Pancake Slip Ring Assemblies

For restricted height situations, a "pancake-style" (or flat-platter style) slip ring is the right solution. We custom-build this type of ring to have anywhere from 4 to 50 conductors with various center bores.

Custom Slip Ring Assemblies

If you need a customized slip ring, look no further than Conductix-Wampfler. We have 60 years experience designing and manufacturing custom slip ring assemblies and enclosures. Using the latest in solid modeling software and CAD/CAM systems, we can go from concept to finished product, and quicker than you thought possible. We have the experience and know-how to fill your slip rings needs!